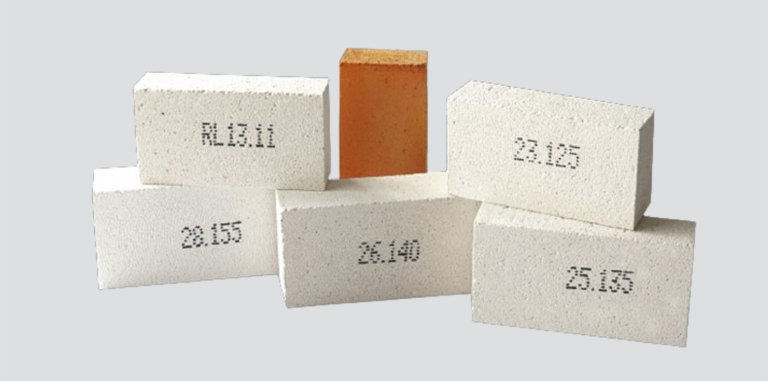

Standard insulating fire bricks

Complete range of insulating fire bricks for industrial applications up to 1550˚C.

- Low thermal conductivity

- High cold crushing strength

- Low permanent linear change

- Sustainable production

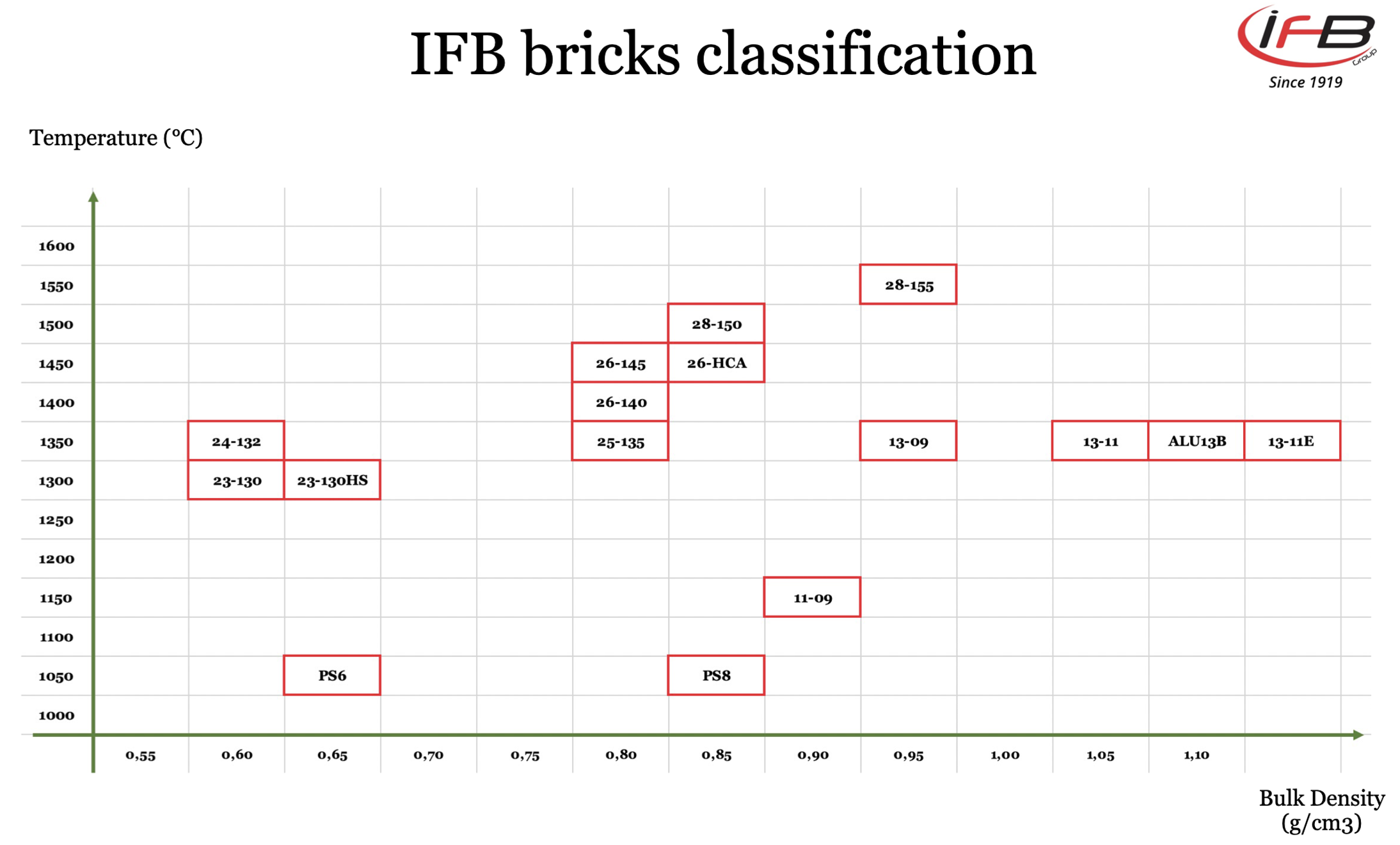

IFB bricks classified by temperature and bulk density. Further details on each bricks available in the product data sheets.

IFB Refractories bricks are 100% made in France, from local raw materials, with a special attention to the environment.

Technical characteristics

The PS range

The PS range is made of globular silica insulation bricks. It has been produced for more than half a century with clay from our own local quarry, hence the ochre colour. It is typically used for external layer applications.

Presentation :

PS6 is a globular silica insulation brick. It has been produced for more than half a century with clay from our own local quarry. It is typically used for external layer applications. The brick exists in trimmed and machined versions. Maximum classified temperature: 1050°.

Maximum classified temperature: 1050°. Bulk Density: 0.65 g/cm3

Bulk Density: 0.65 g/cm3 Globular silica brick. Local organic filler.

Globular silica brick. Local organic filler.

Presentation :

PS8 is a variation of the iconic PS6 brick offering a density at 0.85 g/cm3 and a higher CCS at 4.5 MPa. It has been produced for more than half a century with clay from our own local quarry. It is typically used for external layer applications. The brick exists in trimmed and machined versions. Maximum classified temperature: 1050°.

Maximum classified temperature: 1050°. Bulk Density: 0.85 g/cm3

Bulk Density: 0.85 g/cm3 Globular silica brick. Local organic filler.

Globular silica brick. Local organic filler.

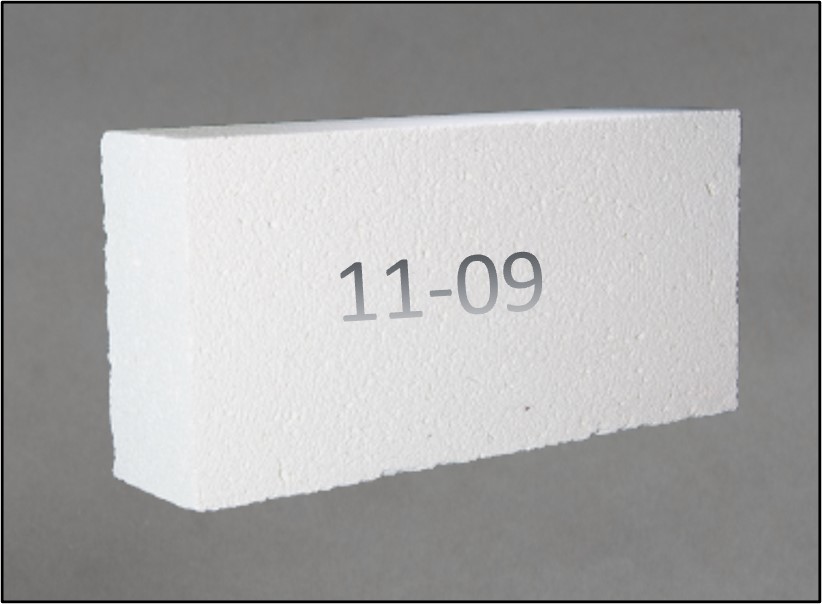

The 11 range

The 11 range encompasses bricks designed for applications that require temperatures as high as 1150°C. These bricks offer a high degree of thermal insulation alongside excellent mechanical properties, making them particularly suitable for various applications. The 11 range is particularly popular in the phosphate industry.

Presentation :

The 11-09 brick is designed for 1150°C temperature applications. It offers a high level of thermal insulation (0.32 W/m.K at 1000°C) with excellent mechanical properties (CCS >3 Mpa). Typical applications include the phosphate industry. The brick exists in trimmed and machined versions. Maximum classified temperature: 1150°.

Maximum classified temperature: 1150°. Bulk Density: 0.92 g/cm3

Bulk Density: 0.92 g/cm3 Globular silica brick. Local organic filler.

Globular silica brick. Local organic filler.

The 23 & 24 range

The 23 & 24 range include some best in class insulating products. It provides a very low thermal conductivity over the whole temperature range. It is particularly well suited for intensive energy saving applications.

Presentation :

The 23-130 brick is IFB 23 class best insulating product. It provides a very low thermal conductivity over the whole temperature range (0.28 W/m.K at 1200°C) and a cold crushing strength over 1 Mpa. It is particularly well suited for intensive energy saving applications. Maximum classified temperature: 1300°.

Maximum classified temperature: 1300°. Bulk Density: 0.58 g/cm3

Bulk Density: 0.58 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

Presentation :

23-130HS (High Strength) is a variation of IFB best insulating brick 23-130 with higher mechanical properties. Its cold crushing strength is over 1.5 MPa while its thermal conductivity remains close to best in class standards. It is well suited for energy saving applications with mechanical requirements. Maximum classified temperature: 1300°.

Maximum classified temperature: 1300°. Bulk Density: 0.67 g/cm3

Bulk Density: 0.67 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

Presentation :

The 24-132 is an evolution of IFB Refractories’ best insulating brick 23-130 designed to reach applications with a temperature up to 1320°C. It offers similar insulating (0.29 W/m.K) and mechanical (CCS >1MPa) properties with an extended temperature range. Typical applications include the glass industry. Maximum classified temperature: 1320°.

Maximum classified temperature: 1320°. Bulk Density: 0.62 g/cm3

Bulk Density: 0.62 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

The 13 & 25 range

The 13 & 25 ranges stand out as IFB Refractories’ most renowned insulating bricks, owing to their exceptional mechanical characteristics. These products have evolved into the industry benchmark for demanding applications, notably in sectors like glass manufacturing.

Presentation :

The 13-09 brick is a lighter version of IFB iconic 13-11 brick. It provides higher insulating properties (thermal conductivities at 0.40 W/m.K at 1000°C) where a medium high mechanical resistance is needed (CCS > 3.5 Mpa) Maximum classified temperature: 1350°.

Maximum classified temperature: 1350°. Bulk Density: 0.93 g/cm3

Bulk Density: 0.93 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

Presentation :

One of IFB Refractories’ iconic products, the 13-11 brick offers high mechanical properties with a cold crushing strength over 6.5 Mpa and a thermal conductivity at 0.44 W/m.K at 1000°C. It has become an industry standard for heavy operations like in the glass industry. Maximum classified temperature: 1350°.

Maximum classified temperature: 1350°. Bulk Density: 1.06 g/cm3

Bulk Density: 1.06 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

Presentation :

A variation of our iconic product 13-11, the 13-11-E brick is best in class in terms of mechanical properties with a cold crushing strength over 8 Mpa and a thermal conductivity of 0.46 W/m.K at 1000°C. It is particularly well suited for very heavy operations like for rotary kilns or in the aluminium industry for anode baking furnaces.

Maximum classified temperature: 1350°.

Maximum classified temperature: 1350°. Bulk Density: 1.10 g/cm3

Bulk Density: 1.10 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

Presentation :

The lightest brick of the 13 & 25 range with a bulk density at 0.8 g/cm3 and a classification temperature at 1350°C. The brick offers excellent insulation properties (0.36 W/M.K). It is an ideal choice for applications where a compressive strength (CCS) exceeding 2 MPA is not required.

Maximum classified temperature: 1350°.

Maximum classified temperature: 1350°. Bulk Density: 0.80 g/cm3

Bulk Density: 0.80 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

The Alu-13B

The ALU type complies with the specifications for aluminium pots applications. Also called BIR, it offers both high insulating and mechanical properties. As it might come in contact with aluminium or fluorinated sodium, its resistance to corrosion is strong.

Presentation :

The ALU-13B insulating brick complies with the specifications for aluminium pots applications. Also called BIR, it offers both high insulating and mechanical properties. As it might come in contact with aluminium or fluorinated sodium, its resistance to corrosion is good.

Maximum classified temperature: 1350°.

Maximum classified temperature: 1350°. Bulk Density: 1.08 g/cm3

Bulk Density: 1.08 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

The 26 range

IFB 26 range is designed for 1400°C temperature applications. It offers a solid level of insulation and a high level of mechanical resistance. It is compatible with most kind of industrial applications.

Presentation :

The ALU-13B insulating brick complies with the specifications for aluminium pots applications. Also called BIR, it offers both high insulating and mechanical properties. As it might come in contact with aluminium or fluorinated sodium, its resistance to corrosion is good. Maximum classified temperature: 1400°.

Maximum classified temperature: 1400°. Bulk Density: 0.87 g/cm3

Bulk Density: 0.87 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

Presentation :

The 26-145 brick is IFB classical insulating brick for 1450°C temperature applications. It offers a good level of insulation (0.38 W/m.K at 1000°C) and a cold crushing strength > 2 Mpa. It is compatible with most kind of industrial applications. Maximum classified temperature: 1450°.

Maximum classified temperature: 1450°. Bulk Density: 0.78 g/cm3

Bulk Density: 0.78 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

Presentation :

The 26-HCA is an evolution of the 26-140 brick with a Higher Alumina Content (>57%) and lower iron oxide (<1.1%). It provides similar insulation (0.38 W/m.K at 1000°C) and mechanical (CCS>2,7 MPa) properties.

Maximum classified temperature: 1450°.

Maximum classified temperature: 1450°. Bulk Density: 0.85 g/cm3

Bulk Density: 0.85 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

The 28 range

The 28 range represents IFB’s classical insulating brick series designed for applications at temperatures up to 1500°C. Featuring a high alumina content and low iron oxide, it provides exceptional insulation and strong mechanical properties.

Presentation :

The 28-150 is IFB classical insulating brick for 1500°C temperature applications. With high alumina content (>58%) and low iron oxide (<1.05%) it offers high insulation (0.39 W/m.K at 1200°C) and good mechanical properties (CCS >2.2 MPA). Maximum classified temperature: 1500°.

Maximum classified temperature: 1500°. Bulk Density: 0.87 g/cm3

Bulk Density: 0.87 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.

Presentation :

The 28-155 is IFB classical insulating brick for 1550°C temperature applications. With high alumina content (>60%) and low iron oxide (<1.05%) it offers high insulation (0.40 W/m.K at 1200°C) and excellent mechanical properties (CCS >3 MPA). Maximum classified temperature: 1550°.

Maximum classified temperature: 1550°. Bulk Density: 0.94 g/cm3

Bulk Density: 0.94 g/cm3 French refractory clays & local organic filler.

French refractory clays & local organic filler.